Summer of Making 2016

Ready, set, MAKE!

The White House and Congress are hosting Maker Faires to kick off the National Week of Making June 17 to 23, while European Maker Week will feature dozens of events from FabLabs to stool-making workshops.

Then get ready for Maker Camp, a virtual DIY camp for teens 13 to 18 years of age sponsored by Make: magazine. Free and open to all on Google+, the camp runs from early July until mid-August and there is no registration–just go on any day you wish.

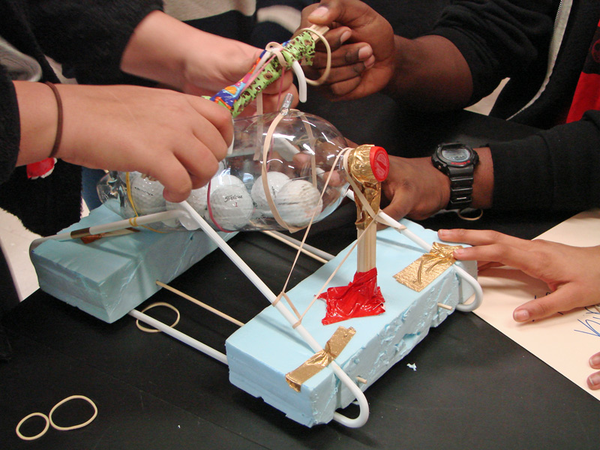

A new project is introduced each morning by an expert camp counselor, who will give campers tips and advice on successfully building the project. Past projects have included making robot key chains and cyborg prosthetic limbs. Materials lists for projects are posted in advance to allow time to find supplies needed for the next day’s project. In the afternoon, campers can join the counselor to talk about the project and look at photos campers have submitted. Click HERE to see videos and YouTube playlists from previous Maker Camp projects.

No Internet connection? No problem! Libraries, schools, and museums across the country are hosting maker camps this summer. Find a local makerspace near you.

There is an age restriction to create a Google+ profile and attend hangouts. Campers under 13 can attend Maker Camp on Google+ with a parent, using his or her Google+ profile.

Filed under: K-12 Outreach Programs, Special Features, Web Resources | Comments Off on Summer of Making 2016

Trying to resuscitate your cellphone that just fell in a puddle – or persuade a doubting Thomas about climate change?

Trying to resuscitate your cellphone that just fell in a puddle – or persuade a doubting Thomas about climate change?

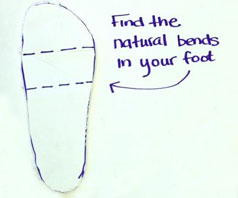

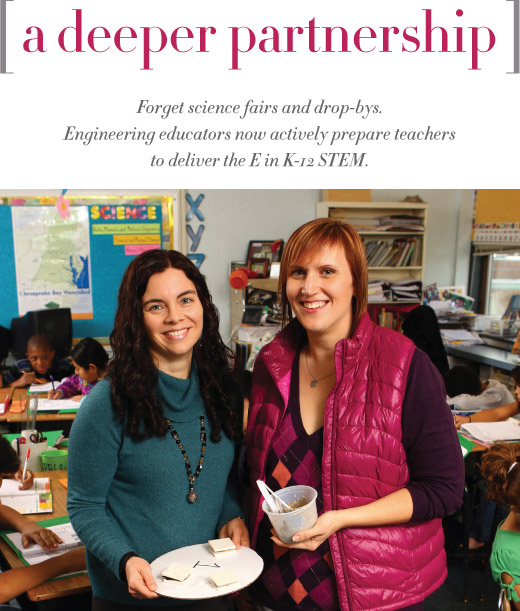

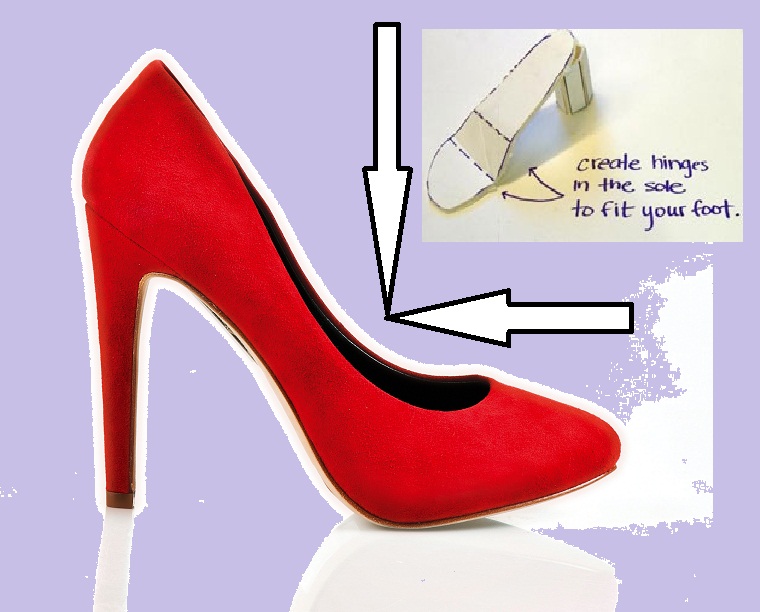

In this activity, students will use foam board for the soles.

In this activity, students will use foam board for the soles.