Tunnel Through!

TeachEngineering activity contributed by the University of Colorado-Boulder College of Engineering’s Integrated Teaching and Learning Program.

Summary

Students apply their knowledge about mountains and rocks to transportation engineering to develop a model mountain tunnel that simulates the principles behind real-life engineering design. Student teams design and create model tunnels through a clay mountain, working within design constraints and testing for success; the tunnels must meet specific design requirements and withstand a certain load.

Grade level: 6 to 8

Time: 1 hour, 45 minutes (two 50-minute class periods)

Engineering Connection

To support our world’s high demand for transportation routes, many types of engineers (civil, environmental, architectural, mechanical, electrical, etc.) work together to ways to create safe and efficient travel through mountains, over water, and in varying climates. Creation of tunnel boring machines (TBMs) improved the process of drilling through rock with an alternative to drilling and blasting methods. Mountain tunnel construction using TBMs results in smooth tunnel walls, reducing the costs of lining the tunnel, and causes fewer disruptions to the surrounding natural environment. Additional tunnel and roadway engineering tasks include design of air quality testing, ventilation and lighting systems; back-up generators; and safety considerations.

Learning Objectives

After this activity, students should be able to:

- Describe the process used in creating mountain tunnels.

- List several types of engineers that are involved in the final design of a mountain tunnel.

- List several engineering design constraints involved in the creation of a mountain tunnel.

Educational Standards - NGSS: Next Generation Science Standards – Science

Common Core State Standards – Math

International Technology and Engineering Educators Association – Technology

State Standards

Suggest an alignment not listed above

Materials List

Each group needs:

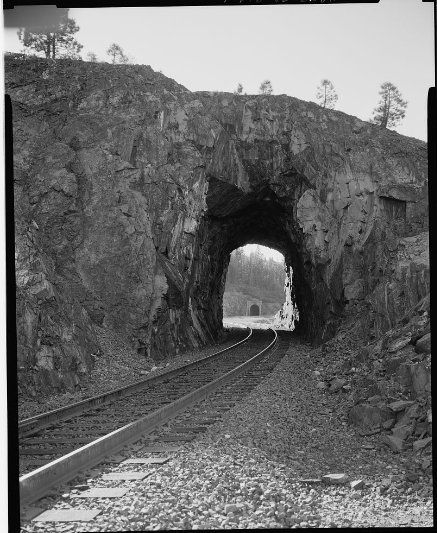

Transcontinental Railroad tunnels like this Central Pacific Tunnel 4 in Cisco, Calif., were cut by hand using pickaxes and dynamite. Photo from Library of Congress.

Learning standards

Next Generation Science Standards

- Define the criteria and constraints of a design problem with sufficient precision to ensure a successful solution, taking into account relevant scientific principles and potential impacts on people and the natural environment that may limit possible solutions. [Grades 6 – 8]

Common Core State Mathematics

Solve real-world and mathematical problems involving area, volume and surface area of two- and three-dimensional objects composed of triangles, quadrilaterals, polygons, cubes, and right prisms. [Grade 7]

International Technology and Engineering Educators Association

- Transporting people and goods involves a combination of individuals and vehicles. [Grades 6 – 8]

- Modeling, testing, evaluating, and modifying are used to transform ideas into practical solutions. [Grades 6 – 8]

Materials

Each group needs:

- 10 Popsicle sticks

- five 10 cm lengths of wire or pipe cleaner

- cardboard square, at least 20cm square (for a student working surface)

- clay (~ 15cm x 12cm)

- plastic spoon

- pencil or wooden dowel

- Tunnel Engineering Design Worksheet [PDF]

- (optional) Other objects around the classroom that could be used as tools for boring tunnels through clay

For the entire class to share:

- glue

- rulers

- water

- weights or heavy objects to use as weights (such as books)

Introduction/Motivation

What are the different ways that people can travel or transport items to a city on the other side of a mountain? Well, they can usually travel over the over the mountain or through the mountain. What are the advantages to having a mountain tunnel for transportation? What about weather? Is the driving weather more likely to be better on top of a mountain or inside of it? Fog and snow at high mountain elevations are more likely to cause roads that cross over mountains to be closed, while roads passing through are safe and dry inside! The engineering of mountain tunnels allows us to transport goods and people through mountains in much less time than driving over or around a mountain. Approximately one-quarter of the Earth’s landmass is covered with mountains, so ways to cross around or through mountains make up a substantial part of transportation engineering.

The Gilman Tunnels in the Jemez Mountains of New Mexico was originally blasted out of the rock in the 1920’s for a logging railroad and offer spectacular views of striking mesas. USDA Forest Service photo by Jeff Harris.

The methods used for mountain tunnel construction are distinctive from those used for various other types of tunnel construction. Because mountain tunnels are often created by making a hole through sturdy rock layers, the process requires very little extra support during construction. For example, during underground tunnel construction, lumber forms are usually needed to keep the surrounding soil area from caving in. Mountain conditions, however, naturally provide sturdy rock surroundings during the drilling, eliminating the need for supplemental support. Since it is possible for different layers and hardness of rocks to be present within a mountain area, engineers determine the types of rock in the mountain before any construction begins. Sometimes engineers use materials to reinforce the interior of a tunnel from shifting rocks.

When engineers first started designing tunnels through mountains, they used the tools and process available at the time — mostly dynamite explosives. One drawback of this approach was the unintentional side effect of creating “sinkholes” inside the tunnel. Sinkholes in the tunnel floor required the addition of concrete or other material to even up the roadway inconsistencies. Today, however, engineers have developed new technologies that help them drill through mountains. Tunnel boring machines (TBMs) can bore through everything from hard rock to fine sand, and the machines themselves can m_easure up to 15 meters in diameter! Unlike the unconstrained techniques involving blasting, mountain tunnel construction using TBMs produces smooth tunnel walls with fewer disruptions to the surrounding natural environment.

Engineering of mountain tunnels goes far beyond boring enormous holes through mountain sides. Engineers also design air quality testing and ventilation systems, safety factors, lighting systems, and back-up generators for tunnel power — among countless other details necessary to make tunnels ready for transportation. This means architectural, environmental, civil, mechanical and electrical engineers are all involved in the final design of a mountain tunnel.

Today, you are going to practice being a transportation engineer with the assignment of designing a tunnel to go through a mountain. You will create and test a model of your design and explore design improvements.

Procedure

Before the Activity

Gather materials and make copies of the Tunnel Engineering Design Worksheet, one per team.

Make model clay mountains (mounds) that are ~ 12cm high by 15cm in diameter. Place each mountain on a piece of cardboard. Make enough for one per group.

With the Students: Day 1-Tunnel Design

Review the overall activity procedure with the students: Working in teams, you will design and create model tunnels through your clay mountains. On Day 1, you will design your procedures for boring rock out of the mountain, and build your tunnels. On Day 2, you will test your tunnels by 1) pouring water over the mountains to test for cracks or openings, and 2) applying weight to test your tunnels for structural strength.

Review the engineering design constraints: Each team’s final tunnel will be rated (given points) for meeting the following design requirements:

- Tunnel dimensions: Each group’s tunnel must measure at least 4cm wide by 6cm high and go completely through the mountain.

- The amount of material used in tunnel development and construction (Engineers strive to create the best structure possible by using the fewest materials as possible, hence, the least costly!)

- Completed tunnel development in the assigned time period

- Insulation of tunnel from weather (no water leaks into the tunnel)

- Structural strength (The mountain does not collapse under added weight)

- Environmental impacts (Does the tunnel change the mountain structure?)

Divide the class into groups of two students each.

Distribute the worksheet. Have each group brainstorm how they will bore a hole through their mountain and sketch their tunnel design idea on the worksheet. Remind students that engineers do not just start building — they carefully discuss and design first!

Distribute materials and model clay mountains to each group.

Give students a limited amount of time (~ 30-40 minutes) to construct their tunnels through their clay mountains on their cardboard bases.

With the Students: Day 2-Tunnel Testing

Have students take turns testing their tunnel structures for cracks (by pouring water over their structure while at a sink or over a large basin) and structural strength (by placing weights or heavy books on their mountain top).

- Assign points to each group and determine the winning team. (35 possible points)

- Tunnel dimensions: Each group’s tunnel must measure at least 4cm wide by 6cm high and go completely through the mountain. (5 points)

- The amount of materials used in tunnel development and construction (1 bonus point for each provided Popsicle stick or wire piece that a team does not use)

- Completed tunnel development in the assigned time (5 points)

- Insulation of tunnel from weather (no water leaks in) (5 points)

- Structural strength (The mountain does not collapse under added weight) (5 points)

- Environmental impacts (Tunnel does not change mountain structure) (5 points)

Lead a class discussion about what worked, what did not work, and why. See the engineering communication and environmental impacts suggestions in the Assessment section. If time permits, give teams time to redesign their structures based upon their tests.

Re-test new designs and see if improvements were made.

Assessment

Pre-Activity Assessment

Brainstorming: Ask students some open-ended questions to get them thinking about mountains and tunnel construction. Remind students that in brainstorming, all ideas should be respectfully heard; no idea or suggestion is “silly.” Take an uncritical position, encourage wild ideas and discourage criticism of ideas. Have students raise their hands to respond.

Ask the students: Who has driven through a mountain before? How do you think engineers built the tunnel? Would you rather drive over a mountain or through one? Why?

Class Discussion: As a class, discuss what engineers who are designing a mountain tunnel should consider in their design about the rock layers? (Possible answers include: What type of rock[s] and soil are in the mountain, how soft or hard the rock[s] is, are any different rock layers present in the mountain.)

Activity Embedded Assessment

Observations: Observe each team as they create their models. Engage them with questions about their design and construction choices, such as: Why did you decide on this design? Do you think this design is sturdy? Why did you decide on this method/approach? What tools do you have that would be most effective at tunneling through the mountain? Why? How is your tunneling impacting the mountain? Did you reinforce your tunnel? Are you using your time and materials wisely?).

Post-Activity Assessment

Engineering Communication: As a class, discuss the various tunnel models created by the teams. If the class size allows, have students teams sit in a circle, each presenting their models to the class and explaining their ideas. Talk about what worked, what did not work, and how they would modify their designs if they could do it all over again.

Environmental Impacts: Have students talk about what they did with the clay that they removed from the mountain while digging their tunnels. How did they dispose of the unneeded material? What could engineers do with the rock and soil removed from mountains as they make tunnels? How might the creation of a tunnel through a mountain change the surrounding environment of the mountain?

Investigating Questions

- Have you ever been in a mountain tunnel? What was it like?

- How do you think engineers create mountain tunnels?

- Why are mountain tunnels important?

Activity Extensions

Have each student research and write about a famous tunnel, describing its unique engineering design challenges. This might include subways and aqueducts, as well as roadway, railroad, utility and underwater tunnels. See the list provided at Wikipedia.

Have students interview local engineers about their experiences with tunnel construction.

Activity Scaling

For lower grades, simplify or eliminate the tunnel dimension requirements.

For upper grades, add design or construction requirements and/or further limit the materials available for their design.

Additional Multimedia Support

Direct students with extra time to WGBH Building Big’s online Tunnel Challenge, at which students can choose a location (through mountain, beneath city or under river), pick a tunnel-digging technique and see how long it takes to dig a mile-long tunnel:

Direct students to learn about tunnel digging tools and techniques (fire-setting, hand tools, explosives, compressed air drill, tunnel boring machine and tunnel shield) at WGBH Building Big’s online website.

References

Building Big: Tunnel Basics. PBS Online, WGBH Educational Foundation.

Contributors: Marissa Hagan Forbes; Malinda Schaefer Zarske; Denise W. Carlson

Copyright © 2008 by Regents of the University of Colorado.

Supporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado Boulder

Acknowledgements

The contents of these digital library curricula were developed by the Integrated Teaching and Learning Program under National Science Foundation GK-12 grant no. 0338326. However, these contents do not necessarily represent the policies of the National Science Foundation, and you should not assume endorsement by the federal government.

Last modified: May 3, 2019

Filed under: Class Activities, Grades 6-8, Lesson Plans

Tags: civil and environmental engineering, Class Activities, Grades 6-8, Lesson Plan, railroad, Transportation, tunnel