Learn to Build a Rocket in 5 Days or Your Money Back

Summary

Elementary students discover the entire process that goes into designing rockets, including what real-world decisions engineers must make. They learn about many important aspects such as supplies, ethics, deadlines, and budgets. They also learn about the engineering design process and that the first design is almost never the final design. Re-engineering is a critical step in creating rockets.

Grade level: 3 -5

Time: 15 minutes

Engineering Connection

When designing rockets, engineers must not only consider how far and fast they need to go, but also how much they cost, how safe they will be, how heavy they will be, and what impact they will have on the environment. Very often, the strongest design is too heavy or too expensive, so the designs evolve to find compromises that satisfy all the project requirements. The revised designs are called design iterations, which means engineers design and test, discover what needs to be fixed and improved, and then redesign and test until they attain a satisfactory final design.

Learning Objectives

After this lesson, students should be able to:

- Define and give an example of a “trade-off” in engineering design.

- Explain that engineering design has several steps, that a first design of a project is rarely perfect, and it may take several redesigns before a project is considered acceptable.

- Give an example of a factor to consider when building a rocket, such as: limited budget, customer needs, time limite, available resources, ethical considerations, environmental considerations, safety considerations, as well as the rocket’s performance.

Learning Standards

Next Generation Science Standards

3-5-ETS1-1. Define a simple design problem reflecting a need or a want that includes specified criteria for success and constraints on materials, time, or cost. [Grades 3 – 5]

International Technology and Engineering Educators Association – Technology

- The use of transportation allows people and goods to be moved from place to place. [Grades 3 – 5]

- Identify and collect information about everyday problems that can be solved by technology, and generate ideas and requirements for solving a problem. [Grades 3 – 5]

- Test and evaluate the solutions for the design problem. [Grades 3 – 5]

Introduction/Motivation

What are some questions that engineers must take into consideration when designing rockets? More specifically, what are Spacewoman Tess and Spaceman Rohan’s needs for their rocket? This is perhaps the most important question because as their engineering team, they are your customers, and you are providing a service to them by designing a rocket that fits their needs. (Write student answers on the classroom board. Likely answers: How high does it need to go? How much weight must it carry? How much can it cost? How safe does it need to be? Is it going to harm the environment? How long do we have to build it? For younger students, you may need to prompt them to get answers.) How will the rocket be used? (Answer: It will carry satellites and a spacecraft for Tess.) How will it be fueled (that is, what type of propellant)? Let’s pause and look at our list. Wow—engineers must think about many factors when designing a rocket (or when designing anything, for that matter).

Let’s think about this question, “How much weight must the rocket carry? What does it need to carry?” Do you recall that our rocket needs to carry satellites for Maya, a spacecraft for Tess, and all the propellant to get the rocket up into space—that adds up to a very heavy load! How might you go about designing a rocket to carry a lot of weight? (Possible answers: put in a huge rocket motor, make the rocket very light, or use a very powerful rocket such as a nuclear rocket.) All of these ideas would likely work, but some of them might not be good matches for the other questions on the board. For example, a bigger rocket can lift more, but it will cost more and might take longer to build. Or, a lighter rocket might be made out of very expensive materials or might not be strong enough to endure the stresses of launch. A nuclear rocket might not be safe and could potentially damage the environment if a disaster occurred during/after liftoff.

When we work to solve an engineering problem, there is not just one right answer—many possible workable solutions can be envisioned. So engineers work together to figure out the best solution for the situation. That means that engineering is a delicate balance between many types of different factors. Engineers call these necessary decisions that affect other actions trade-offs. We might be able to make a super powerful rocket that is inexpensive, but it might be very harmful to the environment. This is the trade-off. A rocket might have some beneficial qualities and some disadvantages. If the bad qualities outweigh the good qualities, then we should look for a different rocket design. When designing a rocket, engineers must keep in mind the rocket’s intended uses, performance, cost, deadlines, safety, weight, controllability, environmental impact, and many other factors that must be carefully balanced in order to create a successful rocket.

Do you think engineers always get a rocket design right the first time? The answer is no! It takes many re-designs to get something as complicated as a rocket right. An engineer calls this process re-engineering. It is simply learning from the mistakes of the past and applying those lessons learned to improve a product. We do that with homework too, right? We learn from our mistakes and do a better job next time.

Today you will learn about the engineering design process and how it applies to designing a successful rocket for Tess, Rohan and Maya.

Lesson Background and Concepts for Teachers

Basic Design Life Cycle

Problem Identification: The first step in the design life cycle is determining the problem—which means really understanding what the customer needs. Engineers are problem solvers; they want to design something that is better than before. Sometimes this involves modifying an old idea and sometimes it means starting from scratch with an entirely new idea. At the beginning of a project, an engineering team starts with a list of requirements—these are the things that the product must do. For a rocket, requirements might include how fast it must be able to go, how safe it must be, how much it can cost, how much it can weigh, and when it must be completed. The requirements define what needs to be done to accomplish the project, or job. It is Then the engineers put their heads together to come up with a solution to the problem that meets all the requirements.

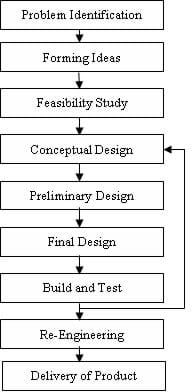

Forming Ideas: The next step in the engineering design process is an idea: “I wonder if…” The idea phase is when a group of engineers brainstorm a lot of ideas that might work as a solution to a problem (see Figure 1). When these ideas are combined, a rough idea for a solution is created.

Feasibility: Next, the engineers decide if the solution they came up with is feasible. Feasibility is not a question of “is it possible” (since little is impossible in today’s high-tech, fast-changing world), but the questions are: can we afford it, is it safe, and is it the right thing to do? Projects are judged for feasibility by a panel of reviewers with strengths and expertise in science, engineering and project management.

Conceptual Design: Once a project is deemed to be feasible, the next step is conceptual design (see Figur 1). The primary questions that are answered during the conceptual design are:

- What is the general configuration of the structure to be built?

- What major trade studies are necessary to conduct (that is, hardware, software, materials)?

- What is it going to cost (calculated estimation)?

- How long will it take (calculated estimation)?

The design that comes out of the conceptual design phase is not the final design, but during this phase many of the important questions about what the final design will look like are answered.

Preliminary Design: If the conceptual design is acceptable, the team moves on to the preliminary design. Actions for the preliminary design are:

- Perform trade studies (decide on best components, materials, etc.).

- Create initial detailed designs.

- Create a detailed schedule and cost plan.

- Further develop concepts with the goal of reducing risk.

- Establish sufficient margins of safety.

Detailed Design: In this phase, the detailed design is agreed upon and finalized. The customer must in agreement with the design budget and schedule before anything moving to the next step.

Build and Test: This is the point when the manufacturing of hardware begins. (Presumably) all design details are complete and every part of the design is ready to proceed into reality. As part of this work, small-scale and/or computer models are often constructed for performance checks and tests. These tests are done with significant margins for error added to each of the tests—making them more extreme than anticipated during the mission. During this review of test results (see Figure 1), any failures or weaknesses in the design must be corrected (back to brainstorming and conceptual or preliminary design) and retested to prove the product fulfills its requirements. Many design iterations are required to refine complicated products.

Product Delivery: Finally, after much hard—yet very satisfying—work, the product is delivered or sold to the customer along with documentation of all tests and operations to prove that the design works.

Re-Engineering

Design, testing and re-design are integral parts of engineering that improves the final product. Nothing is ever just right the first time. Mistakes are inevitably made, but engineers learn from their mistakes, which are used to improve the product during redesigns. Even a design that works can be improved—maybe it can be produced even more inexpensively, maybe it can last longer, maybe it can be faster, etc.

Sometimes the naming of rocket designs included numbers after the rocket or builder names; those numbers indicate the different versions by increasing the number each time they re-design and improve the rocket! Challenge students to complete the associated activity Constraints: Pop Rockets on a Shoestring Budget to re-engineer their pop rockets with imposed limitations of supplies, budgets and deadlines—just like real-world engineers!

Associated Activities

- Constraints: Pop Rockets on a Shoestring Budget – Students re-engineer their pop rockets with imposed limitations of supplies, budgets and deadlines—just like real-world engineers!Watch this activity on YouTube

Lesson Closure

How often do we come across limited resources? Does our playground have enough swings for every student to get his/her own swing? (Answer: No, of course not.) What do you do if there is not enough of something? (Answer: Share.) If three kids are sharing a swing for 10 minutes, is it fair for one to stay on for 30 minutes? (Answer: No.) If your parents gave you a dollar to buy candy, can you buy all the candy in the store? (Answer: No, you must choose from everything available.) How do you decide which candy you will buy? Why is one candy better than another? Would you choose a candy that tastes the best but only lasts 30 seconds or a candy that does not taste as good but lasts for five minutes? Would you make the same choice as your brother or sister? (Answer: It depends on what is valued more: taste or duration of enjoyment.) Sometimes we must make “trade-offs” to get the most out of an object or activity. You may need to tradeoff the length of time on the swing so that everyone gets a swing. You may trade-off how long a candy lasts for one that tastes best to you.

Engineering projects also have trade-offs. Sometimes the trade-off is weight, control or thrust for cost. Sometimes it is the materials available with which they can be built. The engineering process takes many steps to ensure that all the requirements are met, and that is when trade-offs happen. Also, an engineering project is never perfect the first time; it often takes several redesigns to get a solution that meets all the requirements in an acceptable way.

Even with the availability of engineering tools and an understanding of rocket design, an engineering team still needs to be familiar with the steps of the engineering design process to be in tune with the customer’s needs. Hopefully, now as Tess and Rohan’s engineering team, you have all the tools necessary to meet their need to get Maya’s satellites to space and turn Tess’ explorations into reality.

Vocabulary/Definitions

- budget: A detailed plan for the resources and funding available for a project.

- feasibility: Making sure that the basic engineering design is not only possible physically, but that it can be built and satisfy all the requirements, such as speed, weight, power, features, capabilities, budget, timeline, safety, ethics, etc.).

- re-engineering: Learning from mistakes of the first design to improve the next design.

- trade-off: Giving up one thing in return for another.

Assessment

Pre-Lesson Assessment

Prediction: Ask students the following question and have them make predictions. Tally student answers on the classroom board. Tell them that they will learn today whether or not most engineers can design something right on the first try.

- How many of you think that engineers can build a perfect rocket on the first try?

Discussion Question: Solicit, integrate and summarize student responses.

- When a company wants to build a rocket, does someone provide them the materials for free? (Answer: No, cost is a very important consideration in engineering projects. Before a team of engineers receives money to build a rocket, they must have a detailed design that outlines how the rocket will perform, how much it will cost and how long it will take to build.)

Post-Introduction Assessment

Reasonable Question or NOT? Spacewoman Tess, Spaceman Rohan and their daughter Maya are incredibly busy planning their trips. They have given you, as their engineering team, five minutes to ask them a few questions regarding the rocket design. Have the class vote on whether or not the following questions are reasonable questions to ask regarding designing Spacewoman Tess’ rocket:

- What is the purpose of the rocket?

- How much money do we have to build the rocket?

- Should the rocket be pretty or ugly?

- How much time do we have to design and build the rocket?

- When do you need the rocket?

- How long will you need to be in space?

- What are the satellites for?

- When will the satellites need to be in orbit?

- What color should the rocket be?

Brainstorming: In small groups, have students engage in open discussion. Remind them that in brainstorming, no idea or suggestion is “silly.” All ideas should be respectfully heard. Encourage wild ideas and discourage criticism of ideas. Ask the students:

- What are some steps you think engineers need to take as they design rockets? (Prompts: Do they have to think of ideas? Gather materials? Build a model? What else?)

- What are some trade-offs engineers might consider when designing rockets? (Possible answers: safety, cost, materials, launch height, weight, etc.)

Post-Lesson Assessment

Design Flowchart: Assign students to each create a list and description of the steps in an official engineering project. Have them organize these steps in a flowchart format (see Figure 2). Ask the students: What happens when some weakness or problems are discovered during the build and test phase? What would you do? To which step does that take you?

Lesson Extension Activities

Divide the class into small teams. Have each group draw a picture to illustrate each step of the engineering design process. Hang these drawings around the room to remind students of the engineering design process.

Assign students to each research a rocket and write a one-page paper about the engineering history of that rocket. Require them to answer questions such as: How long did it take to design? How much did it cost? What were the rocket requirements? What tradeoffs were made during the design decisions?

Copyright

© 2006 by Regents of the University of Colorado

Supporting Program

Integrated Teaching and Learning Program, College of Engineering, University of Colorado Boulder

Acknowledgements

The contents of this digital library curriculum were developed under grants from the Fund for the Improvement of Postsecondary Education (FIPSE), U.S. Department of Education and National Science Foundation (GK-12 grant no. 0338326). However, these contents do not necessarily represent the policies of the DOE or NSF, and you should not assume endorsement by the federal government.

Last modified: February 25, 2020

Filed under: Class Activities, Grades K-5, Grades K-5

Tags: aeronautical engineering, Class Activities, constraints, earth and space, engineering design proces, Grades K-5, Physical Science, rockets, trade-offs